Let’s talk about LAMPWORKING. A torch, a flame and glass in a molten state!

definition from Merriam-Webster online dictionary

It was the fact that glass could be malleable that blew me away. Glass in a molten, malleable state? Well who knew? That’s how I felt when I first began lampworking. I had never seen glass worked before and I was immediately hooked. I began to set up a studio in my basement before I even finished that first class.

What you’ll need to get started

To begin lampworking you’ll need a torch. I have been using a Nortel Minor since I began lampworking in 2005. It has served me exceptionally well. I can manage to create some pretty big beads with this torch. Although, at this point I’m ready to upgrade to a larger torch. A minor torch is a basic, entry level propane/oxygen mixing torch. Most torches require a source of fuel and heat. The fuel being propane and the heat coming from oxygen. Propane tanks MUST be outside. I have a fuel line feeding through the wall from the tank outside to the torch. My source of oxygen is from an oxygen generator (not pictured) also known as an oxygen concentrator. Suppliers sell oxygen concentrators or you can find sources that refurbish medical grade concentrators. Oxygen can also be purchased by the tank. I started out using tanked oxygen but found I went through oxygen quickly and refilling the tank to be a pain. Many folks wouldn’t use anything but tanked oxygen because it produces a hotter flame. It’s a personal choice to made. Nevertheless, if you’re working large amounts of glass you’ll definitely need a propane/oxygen set up.

There are folks who use Mapp gas. Mapp gas allows you to connect a torch head directly to the small tank and attach/clamp the tank to your bench top and work the glass. I haven’t used Mapp gas so I can’t speak to it but I understand it works reasonably well and is an inexpensive way to get started.

A stainless steel or fire proof work surface is also necessary. As you can see in the photo at the top of the blog I have a stainless steel surface under my work area.

Ventilation is paramount!

I have a fan behind me which blows are toward this fan which ventilates to the outside. I wouldn’t say this is the best set up. One of my goals this summer is to upgrade my ventilation system. A quick and basic explanation of studio ventilation is two fold: remove toxic fumes produced from the burning glass so you’re not inhaling them and replace good air into the studio space.

It is imperative to do your research on ventilation.

The following are a few links to get you started:

Art Glass Answers topic on ventilation

Andrea Guarino-Slemmons covers ventilation.

Aspen Hot Glass has some information on ventilation.

Lampwork etc. is a great resource for lampworkers. I have included a link to the forum on Safety. You must be a member of LE in order to view this link.

A kiln is necessary. After glass has been heated it needs to be tempered at an even temperature for a certain amount of time in order for all the molecules to realign (there’s lots of science and scientific terms for this process but this is the basics of it). A kiln holds the newly formed glass beads at 950 – 960 degrees Farenheit for roughly 15 minutes per 1/4 inch of glass in order for this process to happen. This process is referred to as annealing. Annealing helps the beads to be more stable so they are less likely to break (as long as they are treated properly) and will have a long, happy life in your jewelry designs. When purchasing glass beads it’s to note if the seller states that the beads are annealed.

A variety of kilns exists on the market. Some are small and made specifically for bead makers. A kiln doesn’t have to be as big as mine. I purchased this kiln with the idea I may want to work with other materials. Things to consider when you’re looking for a kiln:

- A bead door. So you can easily flip it up and add your beads without losing all the heat.

- Maximum kiln temperature. Consider future plans and uses.

- Size and placement of the kiln

- Electrical usage

- Voltage capacity – Where can you safely plug it in?

Glass rods! Of course you’ll need copious amounts of glass rods which then leads to figuring out ways to store all these glass rods. I’m ready for a make over of my glass storage too. There are different types of glass available to purchase; boroscillate (commonly referred to as boro) and soda lime (soft glass). These two glasses don’t play nicely together. The Coeffecient of expansion (COE) on these glasses are different and when the two are used on the same bead it is likely the bead will crack. COE refers to the rate at which the glass cools. Again there is science happening here but if one glass cools faster than the other it will shrink up faster and cause the bead to crack. When purchasing glass it’s important to know the COE will match any other glass you’re working with.

Stainless steel rods or more commonly referred to as mandrels are used to create a bead on.

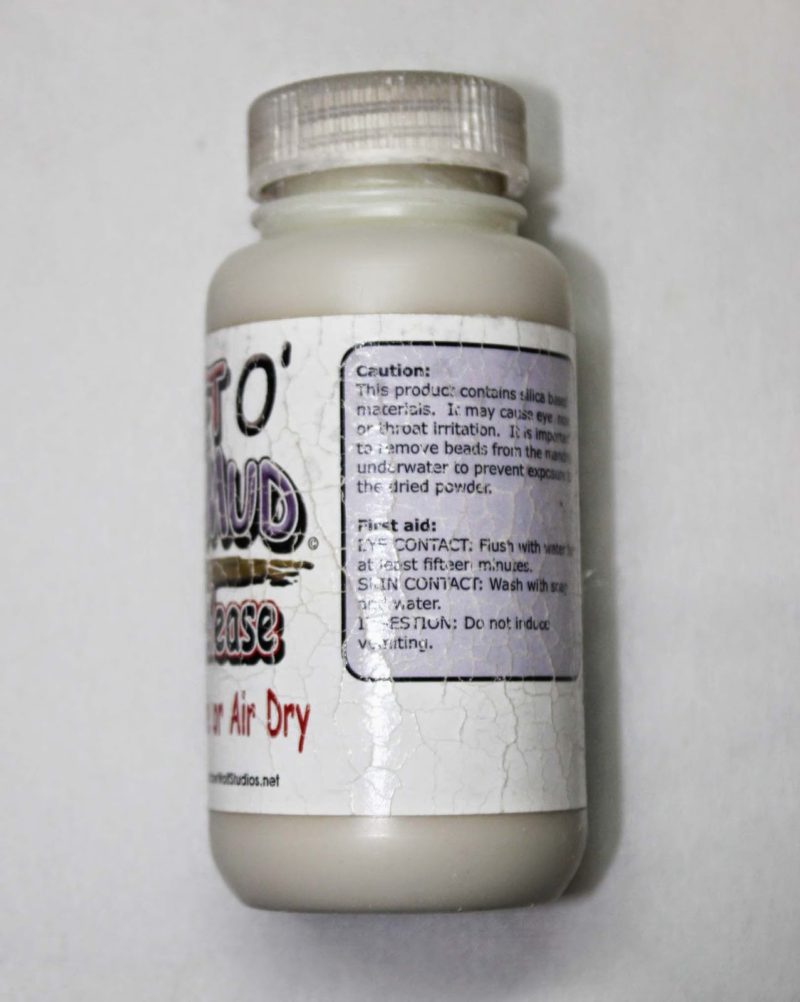

The mandrel must be coated with a release so you can remove the bead from the mandrel after it has been annealed and cooled. I prefer a bead release that can be both air dried and flame dried. I don’t always have the luxury of my schedule being solely my own to make. If I have a couple of hours free and want to fire up the torch I like to have the flexibility to flame dry mandrels.

A good ole fashion coffee can filled with sand serves to hold my mandrels that have been coated in bead release.

Eye protection is at the top of the list of safety concerns. If you’re working with soda lime glass you’ll need a pair of didymium safety goggles to protect your eyes from the flare produce from the melting glass. Wale Apparatus carries a great line of their own safety glasses which have cheater options. I just love that I can change my cheater out without replacing the whole didymium goggle.

Please note that other types of glass requires different types of safety googles.

Tools

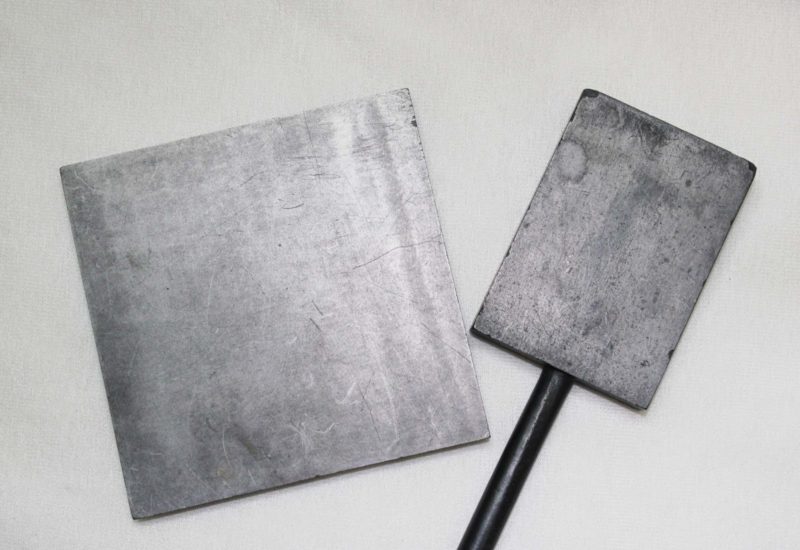

Graphite marvers and paddles act as work surfaces and shaping tools.

Stainless steel tools for shaping, poking, dragging, cutting etc.

Whispering Waves. Swirls created using stainless steel straight tool.

Shaping tools. Lentil press from Jim Morre, Round bead shaper from CG Beadrollers and a small flat press.

Flat masher and my new masher from Arrow Springs (I’m excited about using this one!).

Presses for shaping beads from Zoozis

A mug warmer to warm murrini slices prior to introducing into the flame.

Gulf Side Beach with murrini on a bead

Safety

In addition to eye protection and proper ventilation there are a couple of other safety concerns.

Burns will happen. Be prepared. Always keep a container of water on your bench too. Cold water immediately cools a burn spot.

A safety mask properly rated for the material you’re working with.

I like to use enamels in my beads and when I do I always use a safety mask. I don’t use enamels that often because of the safety risk involved but sometimes inspiration requires enamels.

Transitions Tree of Life with enamals

Resources:

Wale Apparatus – a great source for all things lampwork AND their own line of eyewear which I love

Frantz Art Glass – a great source for all things lampwork

Jim Moore Tools – high quality tools for glass working

CG Beads – variety of bead rollers (as pictured above with the flames on handle)

Zoozis – presses and lampworking tools

.

Thanks for visiting ABS today.

Have you been biten by the lampworking bug?

Do you buy glass beads or are you ready to start making your own?

Ema Kilroy is a lampworker and metalsmith living and working in Central Massachusetts.